Innovations Shaping the Future of Recombinant Antibody Development

Table of Contents

Recombinant antibodies have become a core tool in drug discovery, assay development and mechanistic studies. Researchers depend on them for stable performance across long-term projects, strict batch traceability and flexible engineering options. At the same time, production technologies have progressed from classic hybridoma technology to sequence-defined constructs, advanced expression systems and tightly controlled purification processes.

In this context, supplier selection directly impacts researchers’ data quality. Founded in 2004, Beijing Solarbio Science & Technology Co., Ltd. is an international high-tech enterprise focusing on life science reagents. The company offers more than 200,000 catalog products spanning molecular biology, cell biology, immunology and biochemistry, including over 18,000 antibody items and thousands of proteins, biochemical reagents, small molecule compounds and ELISA kits that have been cited in nearly 150,000 SCI papers worldwide, as summarized per its internal knowledge base. Guided by ISO-compliant quality management systems systems and a one-stop service concept, Solarbio integrates its Products, Solutions and Services platforms so that researchers can move from target selection to validated antibodies and ready-to-use assay components within a unified framework.

What Makes Recombinant Antibodies Central To Modern Biotherapeutics?

Recombinant antibodies are produced from defined DNA sequences rather than genetically unstable hybridoma cell lines that may accumulate mutations or light-chain loss over repeated passages. For researchers, this means that heavy and light chain sequences are preserved, product characteristics can be reproduced consistently on demand and different formats can be generated without additional animal immunization cycles.

Sequence-Defined Molecules With Stable Performance

Once the antibody coding sequence is cloned, each production run utilizes the same construct and the same host cell system. Expression in mammalian cells such as CHO or HEK293 supports appropriate glycosylation for full-length IgG, while microbial hosts are suitable for fragments like Fab or scFv. This sequence definition minimizes clonal drift and lot-to-lot variation, which helps researchers reliably compare datasets generated over months or years.

Solarbio antibodies are produced under stringent quality management systems and purified mainly through affinity chromatography, followed by application-specific validation.These products are tested in Western blotting, immunohistochemistry, immunofluorescence, flow cytometry, immunoprecipitation and genetic knockout models, so researchers can match one clone to several assay formats without repeating basic screening work.

Broad Application Range Across Research And Diagnostics

Recombinant antibodies now appear in therapeutic candidate pipelines, companion diagnostics, biomarker detection panels and high-content imaging platforms. Researchers might employ them as blocking antibodies in functional assays, as capture and detection reagents in ELISA and lateral flow formats, or as precise probes for phospho-epitopes and histone marks in epigenetic studies. Sequence control allows reformatting into humanized, chimeric or fragment constructs when projects move from basic research to translational stages.

Solarbio’s antibody range supports this diversity. According to the internal knowledge base, antibody products span primary and secondary antibodies, tag antibodies, phospho-specific reagents and conjugates, many of which have been used in high-impact studies in oncology, neuroscience and metabolism. Access to such a comprehensive portfolio shortens researchers’ search time and reduces the risk of unvalidated clones entering key experiments.

Solarbio Antibody Portfolio For Routine Workflows

Day-to-day experiments rely on robust antibodies for common targets such as housekeeping proteins, signaling molecules and structural markers. Solarbio’s Antibody catalog lists more than 18,000 antibodies within a broader protein and immunology family that exceeds 8,000 items, embedded in a reagent ecosystem with tens of thousands of supporting biochemical and molecular biology products. The internal knowledge base also records high-impact usage, including primary antibody products cited in journals with impact factors above 30 in chromatin biology and signal transduction.

img.recombinant antibody.png

How Have Expression Systems And Engineering Platforms Evolved For Recombinant Antibody Production?

Expression technology defines how quickly and reliably researchers obtain recombinant antibodies once a sequence is chosen. In recent years, expression platforms and engineering tools have shifted from simple overexpression to finely tuned systems that balance yield, quality attributes and scalability.

Modern Expression Hosts For Different Project Goals

Mammalian systems remain the preferred choice for full-length IgG intended for complex functional studies, since they provide human-like glycosylation and correct protein folding. Fed-batch and perfusion cultivation modes in CHO or HEK293 lines can reach high titers without sacrificing product quality. For screening campaigns and fragment constructs, microbial hosts such as Escherichia coli and yeast offer fast, cost-effective expression that is well suited to early structure–function research.

Solarbio’s CRO platforms cover end-to-end gene-to-protein services for more than a thousand recombinant targets each year across E. coli, insect and mammalian systems. This capacity is important when researchers request custom antibodies, because antigen quality strongly influences the resulting clones. High-purity recombinant proteins or carefully designed peptides help researchers obtain antibodies with high specificity and high affinity.

Display Technologies And High-Throughput Selection

Phage, yeast and mammalian display platforms have changed how antibody libraries are screened. These systems connect genotype and phenotype, so researchers can apply selection pressure for affinity, specificity, epitope coverage or resistance to harsh buffer conditions. Deep sequencing and directed evolution strategies then refine promising sequences by tracking clonal lineages and introducing site-directed mutations.

In practice, this means researchers can obtain functional binders without extensive animal work, particularly when using naïve or synthetic libraries, and without relying exclusively on traditional hybridoma workflows. Recombinant antibodies produced through such cycles often show better expression properties, lower aggregation propensity and improved stability in formulation buffers used for kits and assays.

How Do Process Intensification And Bioreactor Technologies Boost Antibody Yield?

Upstream process design now has a direct impact on researchers’ access to high-quality antibodies. As projects expand and kit volumes rise, suppliers must deliver stable output without delaying timelines or compromising critical quality attributes. Process intensification and modern bioreactor systems have become important enablers for this goal.

High-Cell-Density Culture And Perfusion Strategies

Modern processes frequently employ high-cell-density culture with regulated nutrient feeds. Perfusion systems continuously harvest product-containing medium while retaining viable cells, enabling both higher cumulative yields and more stable culture conditions. This steady physiological environment often improves product quality attributes and supports expression of challenging or sensitive antibody formats. For research-use-only antibodies, this translates into stable supply of catalog products and shorter lead times for custom lots, particularly when multiple formats or conjugates are produced from the same clone.

Because the production model can be repeated across targets, researchers benefit from predictable availability of standard reagents such as loading control antibodies, isotype controls and long-running pathway markers that support time-course and multi-center studies.

Single-Use Bioreactors And Operational Flexibility

Single-use bioreactors have become a standard choice for many recombinant antibody lines. Disposable bags and fluid pathways reduce cleaning validation burden and lower cross-contamination risk when facilities switch between antibodies, recombinant proteins and other biologics. For researchers, this flexibility helps maintain consistent quality when demand for a specific antibody increases suddenly, for example during expansion of a popular assay or kit.

Combined with automated monitoring and control, single-use systems also support small pilot batches for new clones. This capacity is valuable when researchers test custom antibodies under real application conditions before deciding on larger production.

Implications For Solarbio’s Reagent Supply

Solarbio manages a large portfolio that includes more than 93,000 biochemical reagents, nearly 9,000 small molecule compounds, more than 8,000 protein and immunology products and over 18,000 antibodies. Such breadth encourages investment in robust upstream processes, since each process platform supports many catalog items rather than a single product.

What Advances Are Transforming Downstream Purification And Quality Control?

Downstream operations convert cell culture supernatant into final antibody preparations that meet purity and characterization requirements. For recombinant antibodies, chromatography strategies and analytical methods have both advanced significantly, and these developments influence how researchers evaluate suppliers and design their own control plans.

Chromatography Schemes Tailored To Antibody Attributes

Protein A or related affinity chromatography remain the main capture method for IgG antibodies. Newer schemes often apply multi-column configurations or continuous chromatography to improve resin utilization and throughput. Subsequent polishing stages combine ion exchange, hydrophobic interaction and mixed-mode media to remove aggregates, charge variants and host cell impurities specific to each antibody.

Solarbio’s reagent lines include chromatography media and related biochemical reagents that can be used for process development and small-scale purification, as summarized in its product information for chromatography media and analytical tools. When a supplier has access to diverse media and analytical standards, it becomes easier for researchers to obtain antibodies with consistent purity profiles even when batch sizes change.

Advanced Analytical Characterization And Standards

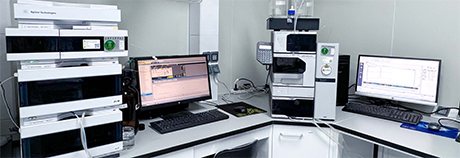

Analytical characterization now employs size-exclusion chromatography, capillary electrophoresis, LC-MS and detailed glycan profiling combined with classic SDS-PAGE. Binding kinetics and functional assays complete the picture by linking structural attributes to biological activity. This level of analysis is important not only for therapeutics but also for antibodies used in kits, where stability and specificity must remain constant between production runs.

Solarbio supports such workflows through its Biochemical Reagent.Analytical standards validated via HPLC, MS and NMR help researchers calibrate instruments and verify methods, while analytical-grade reagents form reliable buffers and reaction systems forquality control assays linked to recombinant antibodies.

Quality Management Systems And Literature Validation

Formal quality systems provide a foundation for these technical activities. The Solarbio holds certifications such as ISO 9001, ISO 14001, ISO 45001 and ISO 13485, which cover quality, environment, occupational health and device-related management across design, production and service. In parallel, extensive literature citations serve as practical validation: Solarbio reports that its products have contributed to nearly 150,000 high-impact papers, with antibody products cited in high-impact journals, including titles whose impact factors exceed 80 according to the internal citation database.

Choosing A Long-Term Partner For Recombinant Antibody Projects

Supplier choice therefore becomes a strategic decision. Besides catalog size and pricing, researchers should consider quality certifications, literature presence, technical support, regional warehousing and participation in international conferences. Solarbio’s About Us and News sections describe its development history, ISO-based systems, regional trading centers and international exhibition activities that support global distribution.

For practical cooperation, researchers can submit project details or technical inquiries via the Contact page. One crucial point is that Solarbio antibodies and related reagents are supplied for research use only and are not intended for pharmaceutical, clinical diagnostic or therapeutic applications, or for food and cosmetic use.

FAQ

Q1: What Are The Main Benefits Of Recombinant Antibodies Compared With Hybridoma-Derived Antibodies?

A: Recombinant antibodies are based on defined DNA sequences and can be reproduced faithfully in suitable expression systems. This reduces hidden variability caused by clonal drift, allows controlled engineering of isotypes and fragments and permits consistent supply over many years, which is vital for regulated assays and long projects.

Q2: How Does Solarbio Support Quality Control For Antibody Products?

A: Antibodies are produced under ISO-aligned quality management systems and purified using affinity and polishing steps appropriate to each product. Validation covers several applications such as Western blotting, IHC, IF, FC, IP and genetic knockout models, and many antibodies appear in peer-reviewed articles, giving researchers both internalquality control data and external performance evidence.

Q3: Are Solarbio Antibodies Suitable For Clinical Or Therapeutic Applications?

A: No. Solarbio antibody products are intended only for scientific research.

Q4: How Can You Initiate A Recombinant Or Custom Antibody Project With Solarbio?

A: You can first check the Antibody catalog to identify existing products, then review pathway pages in Solution for target ideas. If no suitable antibody is available, researchers can submit project details through the Custom Antibody and Contact pages, where technical staff will respond including recommendations, timelines and quotations based on accumulated project experience.